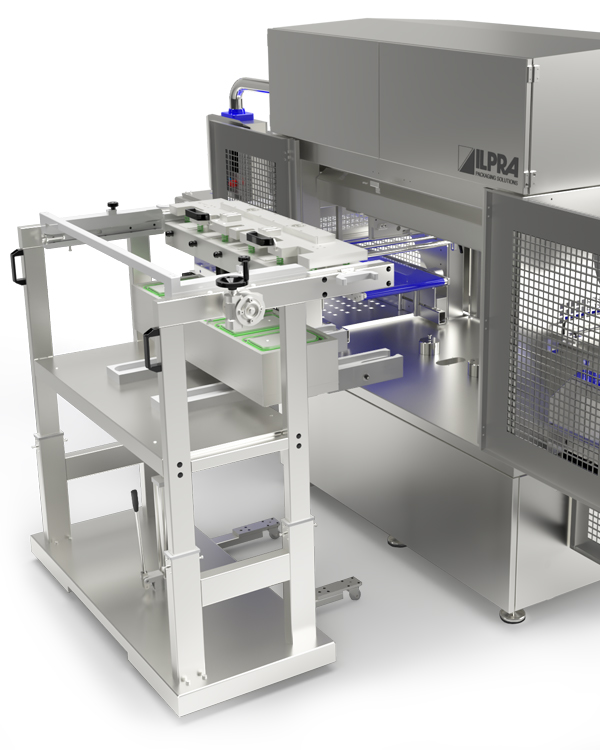

FoodPack Hyper - High performance sealer

FoodPack Hyper Series

High-performance capping machine with patented CPS technology

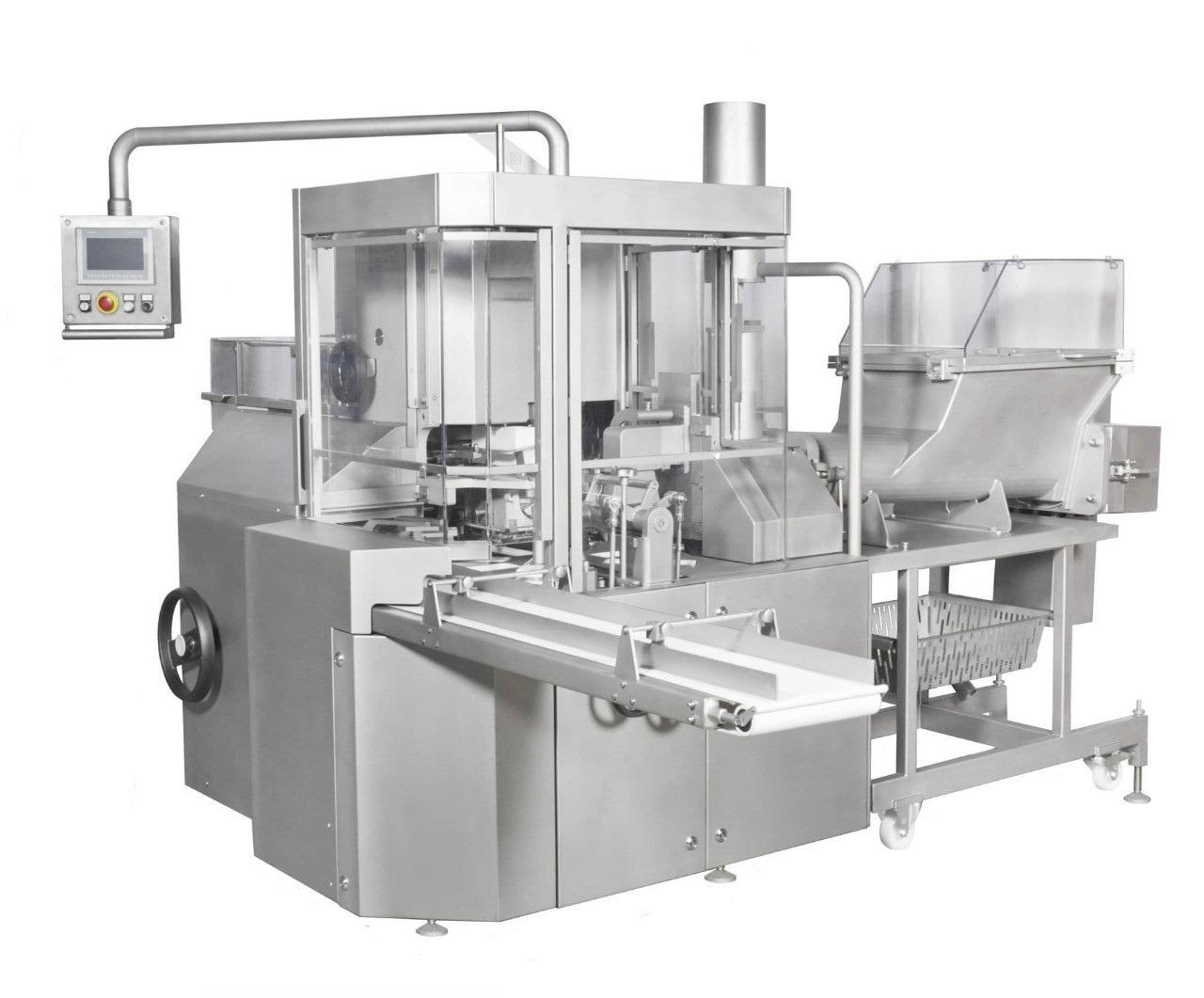

The FoodPack Hyper is a state-of-the-art tray sealer designed for large-scale production. It features the latest CPS (Constant Placement System) technology and offers models such as the 1000 and 1250 versions for fast and efficient packaging.

Type: High-speed automatic capping machine

Application: Large-scale industrial production

Technology: Patented CPS system

Full description

The FoodPack Hyper, available in 1000 and 1250 versions, is designed for high-speed, large-scale production. It incorporates the new CPS technology for continuous tray feeding, which significantly increases production speed.

The machine integrates easily into production lines and includes an anti-crushing system, an identity control system for personnel recognition and predictive maintenance for planning component overhauls.

Details

CPS Technology

This technology significantly improves machine efficiency by allowing trays to flow continuously and seamlessly through the sealing area. Automatic tray separation and transport, achieved through the synchronized movements of the jaws and conveyor belts, ensure fast and uninterrupted packaging operations, thus contributing to increased productivity.

Anti-crushing system

The machine's intelligent photoelectric cell system plays a crucial role in ensuring the safety and integrity of the packaging process. It detects and communicates any misalignment of the trays, triggering an alarm that interrupts the sealing operation. This proactive approach prevents damage to the trays and guarantees consistent product quality.

Mold identification

The FoodPack Hyper's advanced software automatically recognizes different molds, streamlining the setup process. This feature ensures that the correct packaging specifications are consistently applied, improving operational efficiency and reducing the need for manual adjustments.

Predictive maintenance

The PLC's monitoring capability is a remarkable feature, as it provides information for predictive maintenance. By tracking the performance and wear of each component, it anticipates maintenance needs, enabling proactive maintenance and minimizing unplanned downtime.

Technical data

| Setting | Hyper 1000 | Hyper 1250 |

|---|---|---|

| Dimensions (L×l×H) | 422 × 110 × 211 cm | 498 × 110 × 211 cm |

| Total weight | ~2500 Kg | ~3000 Kg |

| Air consumption | 6 bar - 3 Nlt/cycle | |

| Sealing area (L×W×H) | 1000 × 450 × 120 mm | 1250 × 450 × 120 mm |

Technology

- E-MEC Technology: Based on fully electromechanical movements, it increases the speed and productivity of the machine.

- PROGAS system (IPPRA patent): Improves efficiency by reducing gas consumption and increasing working speed.

- Constant Placement System (CPS): Ensures a regular flow of trays, increasing production speed through precise coordination of belts and jaws.

- Identity control system: Badge recognition of authorized personnel with multiple levels of identification.

- Anti-crushing system: Checks the correct positioning of the trays and stops operations to avoid errors in case of misalignment.

- Predictive maintenance: System designed to plan maintenance activities, including the overhaul and replacement of components.

Available options

- ExtraSkin System: Facilitates skin packaging, adapting even to high degrees of protrusion, thus improving versatility and packaging quality.

- Preheating system: Optimizes the skin packaging process by preheating the film, resulting in a more efficient and flexible operation .

Packaging functions

Gas rinsing | Vacuum | Sealing | MAP/ATP | Skin | Chamois leather | Extraskin on cardboard | Extraskin

Demonstration videos

Discover the FoodPack Hyper in action through these demonstration videos and customer testimonials.

Technical Frequently Asked Questions

Improve production

Explore compatible machines

Complete your production line with our range of automated packaging solutions.

Learn moreOther products in this section

Hello! Click below to chat with our team on WhatsApp.