Advanced Mixing and Homogenization System

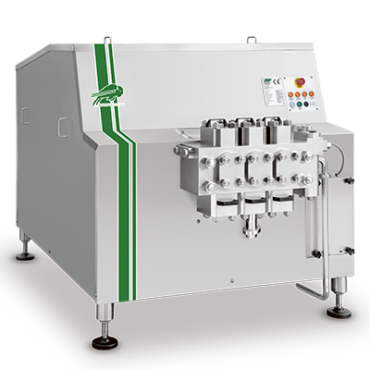

BlendMaster Pro System

Advanced mixing and homogenization technology for dairy products

Our high-performance mixing system is specifically designed for the dairy industry, combining exceptional dosing accuracy with perfect ingredient homogenization. The patented technology ensures complete adherence to your recipes and consistent final product quality.

Type: Automatic mixing and homogenization system

Application: Liquid and semi-liquid dairy products

Advantage: 100% recipe accuracy

Main features of the Mixing System

- Dosage accuracy: ±0.5% for perfect recipe precision

- Processing capacity: 500 to 10,000 liters per batch depending on configuration

- Variable speed stirring system with PID control

- Mirror polished AISI 316L stainless steel mixing tank

- Integrated temperature control from 4°C to 95°C

- Optional high-pressure homogenization system (up to 250 bar)

- Complete automation with control of all process parameters

- Certifications : CE, FDA, EHEDG, 3-A Sanitary Standards

- PLC control with 15" touchscreen HMI interface and data logging

- Integrated CIP automatic cleaning system

Full description

Our BlendMaster Pro mixing system represents the pinnacle of blending technology for the dairy industry. Designed specifically for sensitive products, it combines exceptional dosing accuracy with perfect ingredient homogenization.

The patented agitation technology ensures uniform distribution of all components, preventing areas of concentration that could affect the quality of the final product. The intelligent control system guarantees perfect reproducibility batch after batch, essential for the consistent quality of dairy products.

This system is particularly suitable for dairies seeking to optimize their production processes while maintaining the highest standards of quality and hygiene.

Technical data of the Mixing System

| Setting | Specifications |

|---|---|

| Machine type | Automatic mixing and homogenization system |

| Processing capacity | 500 - 10,000 L/batch |

| Dosage accuracy | ±0.5% |

| Agitation speed | 10-200 RPM (adjustable) |

| Temperature range | 4-95°C with PID control |

| Homogenizing pressure | Up to 250 bar (optional) |

| Operating pressure | Up to 6 bar |

| Materials in contact | AISI 316L, EPDM, Silicone |

| Energy consumption | 15-75 kW depending on capacity |

| Full cycle time | 15-60 minutes depending on the recipe |

| Installed electrical power | 20-100 kW |

Advanced Features and Details

| Standard features | Optional modules |

|---|---|

| High-precision dosing system | High-pressure homogenizer |

| Variable speed agitation | Vacuum system for degassing |

| Integrated temperature control | Steam or electric heating |

| Automatic CIP cleaning | SIP (Sterilize-in-Place) system |

| 15" Touchscreen User Interface | Ethernet connection and monitoring |

| Saving settings | Complete HACCP traceability system |

| Managing multiple recipes | Online density controllers |

| Protection IP65 | Complete hygienic fairing |

FEATURES DETAILS

Intelligent dosing system

Our patented dosing technology guarantees an accuracy of ±0.5% for each ingredient. Integrated mass flow meters and weighing systems ensure strict adherence to recipes, essential for the consistent quality of dairy products.

Optimized agitation

The variable geometry, speed-controlled agitation system ensures homogeneous mixing without air incorporation or excessive shearing. The blade design is optimized for each type of product, from fluid milks to viscous preparations.

Advanced process control

Full automation allows for precise control of all parameters: temperature, mixing time, ingredient addition sequence, and stirring speed. The system records all data for complete traceability and continuous optimization.

Areas of application

Our mixing system is suitable for various applications in the dairy industry:

- Standard and ESL milks - Perfect blend of ingredients and vitamins

- Flavored milks - Uniform distribution of flavors and colors

- Dairy creams and desserts - Homogeneous incorporation of thickeners

- Yogurts and fermented milks - A delicate blend of cultures and fruits

- Cheese preparations - Homogenization of ingredients and additives

Advantages of the mixing system

Optimal product quality

Perfect homogeneity and strict adherence to recipes guarantee consistent quality batch after batch, with perfectly reproducible texture and taste.

Operational efficiency

Complete automation reduces human intervention, minimizes errors and optimizes cycle time, thereby increasing overall productivity.

Improved profitability

Accurate dosing reduces waste of expensive ingredients, while energy efficiency and reduced cycle times optimize operating costs.

Technical Frequently Asked Questions

OTHER PRODUCTS IN THIS SECTION

Hello! Click below to chat with our team on WhatsApp.