UHT Sterilizer - Ultra-High Temperature Processing Technology

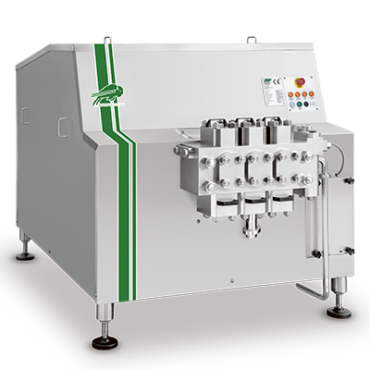

Industrial UHT Sterilizer

Advanced sterilization technology for long-term preservation

Our high-performance UHT sterilizer is designed for ultra-high temperature processing of milk, cream, plant-based drinks, and juices. UHT sterilization significantly extends shelf life without requiring a cold chain.

Type: Direct/Indirect Heating UHT Sterilizer

Application: Milk, creams, plant-based drinks, juices

Advantage: Can be stored for up to 12 months without refrigeration

Main features of the UHT sterilizer

- High-precision UHT treatment: 135-150°C for 2-8 seconds

- Complete elimination of pathogenic microorganisms and spores

- Processing capacity: 200 to 25,000 liters/hour depending on configuration

- Available heating systems: Direct, Indirect or Combined

- Energy recovery > 90% for maximum energy efficiency

- Integrated airless vacuum evaporator for gas and oxygen removal

- Constructed entirely of food-grade AISI 316L stainless steel

- Certifications: CE, FDA, EHEDG, 3-A Sanitary Standards, ISO 9001

- PLC control with 15" touchscreen HMI interface and data logging

- SIP (Sterilize-in-Place) automatic sterilization system

Full description

Our UHT sterilizer represents excellence in the heat treatment of liquid products. Designed to preserve the organoleptic characteristics of the raw material while guaranteeing absolute food safety, it allows for extended storage without a cold chain.

UHT technology maintains the original color, preserves the flavor, and retains the product's taste while eliminating all microorganisms. The modular design allows for adaptation to different types of products and recipes, offering exceptional versatility.

The integrated airless vacuum evaporator eliminates the oxygen responsible for product oxidation, thus preserving quality and extending shelf life. For juices, an aroma recovery system is available.

Technical data of the UHT sterilizer

| Setting | Specifications |

|---|---|

| Machine type | UHT sterilizer with direct/indirect heating |

| Processing capacity | 200 - 25,000 L/hour |

| Sterilization temperature | 135-150°C (adjustable) |

| Holding time | 2-8 seconds |

| Cooling temperature | 20-25°C |

| Energy recovery | > 90% |

| Operating pressure | Up to 15 bar |

| Materials in contact | AISI 316L, EPDM, NBR, PTFE |

| Steam consumption | 50-300 kg/hour depending on capacity |

| Cooling water consumption | 5-15 m³/hour |

| Installed electrical power | 25-120 kW |

Advanced Features and Details

| Standard features | Optional modules |

|---|---|

| High-efficiency plate/tubular heat exchanger | Direct heating system by steam injection |

| Temperature-controlled holding section | Aroma recovery system for juice |

| Automatic CIP cleaning | SIP (Sterilize-in-Place) sterilization |

| Integrated airless vacuum evaporator | Online conductivity and pH controller |

| 15" Touchscreen User Interface | Ethernet connection and SCADA supervision |

| Recording of HACCP parameters | Complete traceability system |

| Aseptic automatic diverter valve | Online spore analyzer |

| IP66 protection | Complete aseptic hygienic enclosure |

FEATURES DETAILS

Airless vacuum evaporator

The airless evaporator operates under vacuum to remove air and dissolved gases from the product, as well as the oxygen responsible for oxidation. For milk, it acts as a deodorizer, eliminating unwanted aromas. For juices, it incorporates an aroma recovery system that condenses and reintroduces the aromas into the product.

Multiple heating systems

Three technologies are available: direct steam injection heating for high-density products, indirect heat exchanger heating for high energy efficiency, and a combined system for maximum versatility. The UHT-Flexy direct system is specifically designed for whipped cream, pastry cream, and high-density products.

Automation and advanced control

The PLC control system with a touchscreen HMI interface enables precise management of all process parameters. Automatic data logging ensures traceability and compliance with HACCP standards. Remote supervision allows for monitoring and predictive maintenance.

Areas of application

Our UHT sterilizer is suitable for various applications in the food industry:

- UHT milk - Can be stored for up to 12 months without refrigeration

- UHT creams - Whipped cream, pastry cream, fresh cream

- Plant-based drinks - Almond milk, soy milk, oat milk, rice milk

- Fruit juices - Pure juices, nectars, smoothies

- Culinary preparations - Sauces, soups, dessert mixes

Advantages of UHT treatment

Absolute food safety

The complete elimination of pathogenic microorganisms and spores guarantees maximum food safety. The sterilized product does not require a cold chain, reducing the risk of contamination.

Extended Market

Long-term storage allows access to wider geographical markets without the logistical constraints of refrigeration, opening up new business opportunities.

Preservation of quality

Unlike traditional sterilization methods, UHT technology better preserves the nutritional qualities, color, and original flavor of products while ensuring long shelf life.

Technical Frequently Asked Questions

OTHER PRODUCTS IN THIS SECTION

Hello! Click below to chat with our team on WhatsApp.