Evaporators and Condensers

Complete solutions for refrigeration systems

The evaporator is the component in a refrigeration system where the refrigerant vaporizes and absorbs heat. It absorbs ambient heat and cools the inside of the appliance. The condenser, on the other hand, condenses the vaporized refrigerant and releases heat. These components play a vital role in systems such as air conditioners and refrigerators. The evaporator transforms the liquid into vapor at low pressure, while the condenser transforms the vapor into liquid at high pressure, thus facilitating heat transfer.

Evaporator: Heat absorption by vaporization

Condenser: Heat release through condensation

Applications: Refrigeration and air conditioning systems

Caractéristiques principales des évaporateurs

- Conception optimisée pour une efficacité maximale du transfert de chaleur

- Matériaux résistants à la corrosion : acier inoxydable, cuivre, alliages spéciaux

- Plage de température : -50°C à +150°C selon l'application

- Pression de service jusqu'à 35 bar

- Surfaces d'échange thermique à haute performance

- Faible perte de charge pour une économie d'énergie optimale

- Certifications CE, ISO 9001:2015, normes frigorifiques

Caractéristiques principales des condenseurs

- Conception robuste pour une dissipation thermique efficace

- Tubes en alliages spéciaux pour applications marines (eau de mer)

- Plage de température : -20°C à +200°C

- Pression de service jusqu'à 40 bar

- Options de refroidissement : air, eau, évaporatif

- Faible entretien et longue durée de vie

- Certifications sectorielles reconnues

Types of evaporators and their applications

Plate evaporators

These evaporators optimize the heat exchange surface area and accelerate heat transfer by maintaining the liquid in a thin layer. They are generally preferred for processing viscous liquids and offer high heat transfer efficiency.

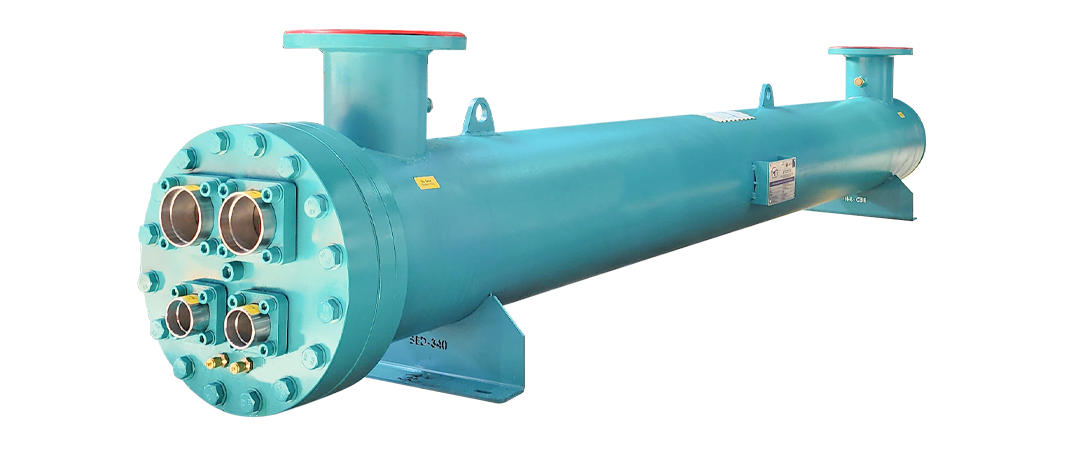

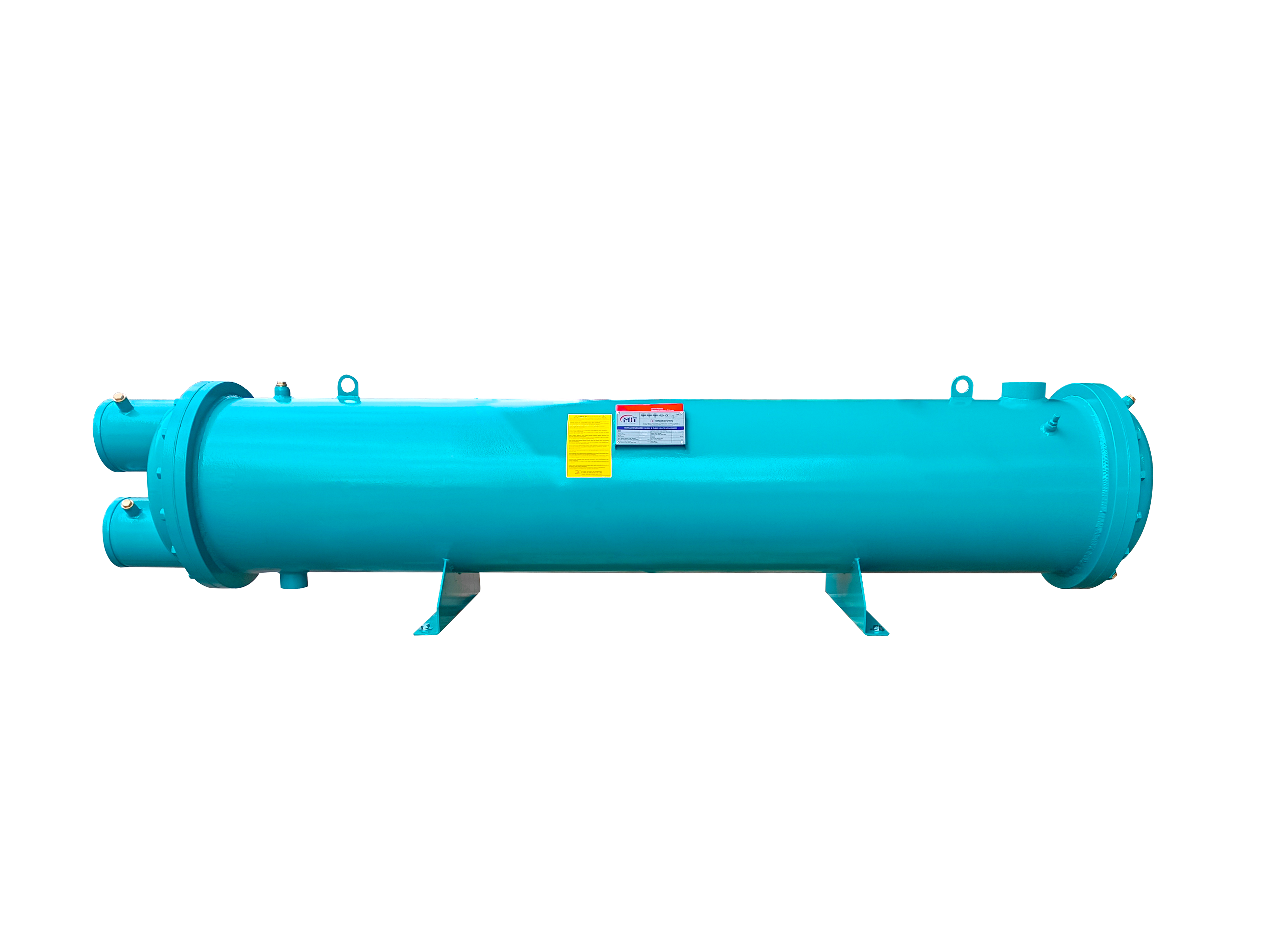

Tubular evaporators

Ideal for a wide variety of high-temperature resistant chemical liquids. The steam or hot liquid flowing through the tubes is efficiently heated. Suitable for applications requiring high temperatures.

Rotary evaporators

Primarily used in laboratories for separating small quantities of solutions. They evaporate a solution by heating it in a rotating flask, allowing for rapid and efficient evaporation. Ideal for quickly removing solvents from solutions.

Types of condensers and their specific characteristics

Air condensers

Areas of application: Small-scale commercial refrigeration systems, air conditioning systems

Features: Fan-generated airflow cooling, low water consumption, easy installation

Water-cooled condensers

Areas of application: Large industrial facilities, thermal power plants

Features: Direct contact with water or aqueous solution, high thermal efficiency, suitable for high capacities

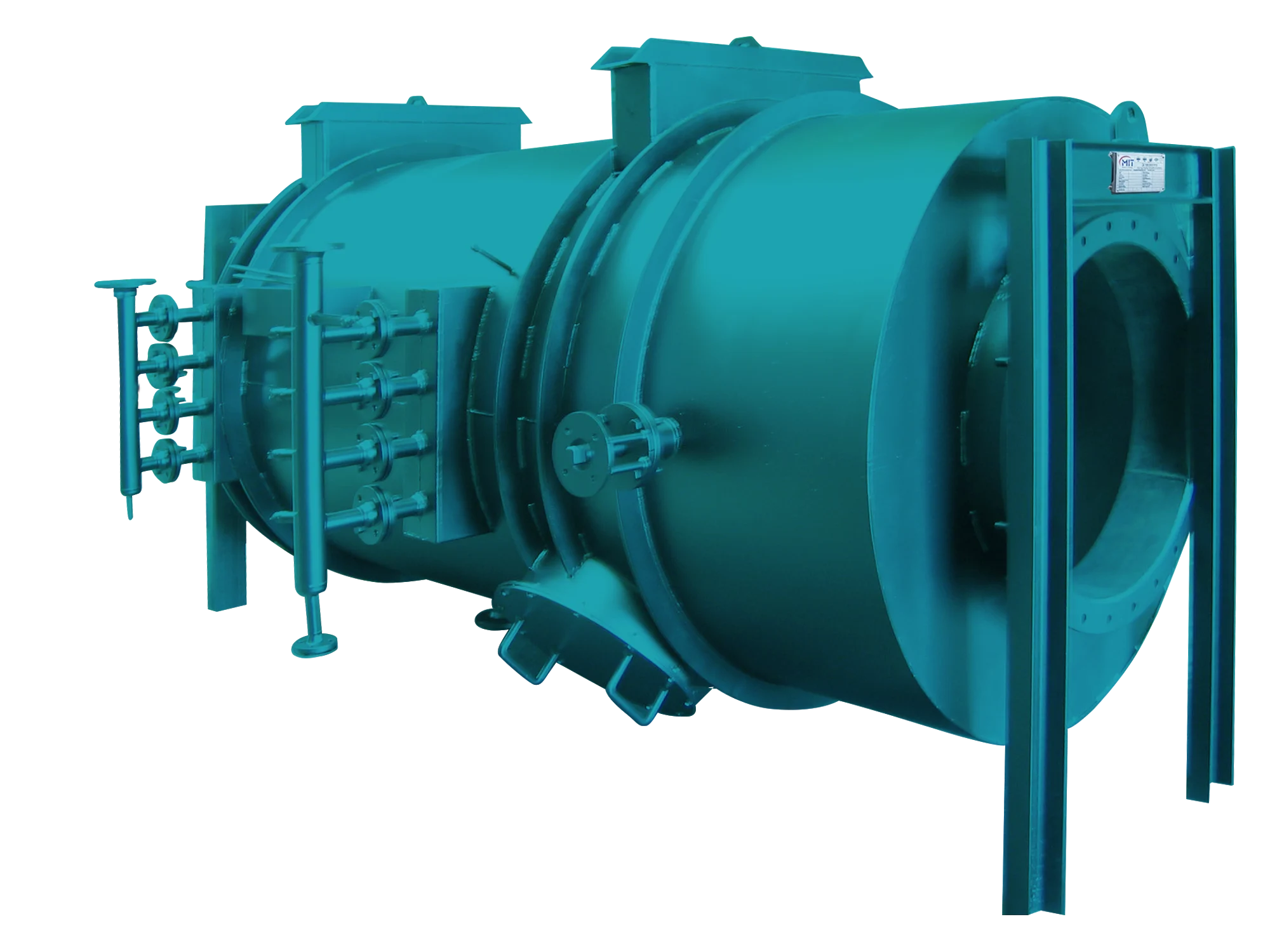

Evaporative condensers

Areas of application: Industrial installations with significant cooling requirements, regions with hot climates

Features: Utilizes the principle of water evaporation, excellent energy efficiency, significant water savings

Seawater tubular condensers

BCM series marine condensers, essential components in the maritime industry, offer excellent seawater compatibility thanks to their special alloy tubes. They condense the high-temperature, high-pressure refrigerant gas from the compressor using seawater. These condensers hold recognized quality certifications in the maritime sector and are among the most sought-after brands on the global market due to the quality of the materials used and their advanced design.

Domaines d'application industriels

| Secteur industriel | Applications spécifiques | Avantages |

|---|---|---|

| Agroalimentaire | Réfrigération industrielle, congélation, conservation des aliments, production de concentrés de jus | Hygiène optimale, surfaces lisses, conformité aux normes alimentaires |

| Automobile | Climatisation véhicules, systèmes test environnementaux, cabines de peinture | Fiabilité élevée, résistance aux vibrations, compacité |

| Marine | Systèmes réfrigération navale, climatisation marine, condenseurs eau de mer | Résistance corrosion marine, conception compacte pour espaces limités |

| CVC | Climatisation bâtiments, pompes à chaleur, production eau glacée | Haute efficacité énergétique, faible niveau sonore, longue durée de vie |

| Pétrochimie/Pharma | Procédés de refroidissement, condensation de vapeurs, contrôle température réacteurs | Résistance chimique, sécurité des procédés critiques, conformité GMP |

| Métallurgie | Refroidissement machines, systèmes hydrauliques, traitement thermique | Robustesse extrême, résistance températures élevées |

| Énergie | Centrales électriques, cogénération, systèmes de récupération de chaleur | Performance optimale, efficacité énergétique maximale |

| Textile | Contrôle température ateliers, séchage, traitement fibres | Précision thermique, fiabilité continue en production |

Fonctionnement des systèmes frigorifiques

Évaporateur

- Absorption de chaleur par vaporisation du fluide frigorigène

- Transformation du liquide en vapeur à basse pression

- Refroidissement de l'environnement ou du produit

- Élément essentiel des cycles de réfrigération

Condenseur

- Libération de chaleur par condensation du fluide

- Transformation de la vapeur en liquide à haute pression

- Dissipation de la chaleur vers l'environnement

- Complément indispensable à l'évaporateur

Specific applications of evaporators

Cooling systems

Evaporators are essential components of cooling equipment:

- Domestic and industrial refrigerators and freezers

- Air conditioning systems and heat pumps

- Industrial process cooling

- Food and pharmaceutical product preservation

Industrial evaporation

In industrial processes, evaporators are used to:

- Focusing solutions in the chemical industry

- Producing concentrates in the agri-food industry

- Treating wastewater and recovering solvents

- Purify pharmaceutical products

Condenser design and selection

Design factors

The design of the condenser directly impacts the system's efficiency:

- Capacity and sizing adapted to the requirements

- Material selection based on corrosion resistance

- Optimizing energy efficiency

- Ease of upkeep and maintenance

Maintenance and durability

To guarantee performance and longevity:

- Regular cleaning of exchange surfaces

- Leak testing and component inspection

- Thermal performance monitoring

- Prevention of corrosion and blockages

Tailor-made solutions and technical expertise

Our team of expert engineers, combined with our know-how in customized solutions, ensures high-performance and reliable cooling systems. Our products offer ideal solutions for industrial refrigeration, commercial refrigerators, air conditioning systems, heat pumps, and many other applications.

Materials used

Depending on the requirements of the process, we use the following materials: Stainless steel, copper, titanium alloys, carbon steels and other specific materials suitable for corrosive environments or particular hygienic requirements.

Frequently Asked Questions

Fluid Transfer Products

Hello! Click below to chat with our team on WhatsApp.