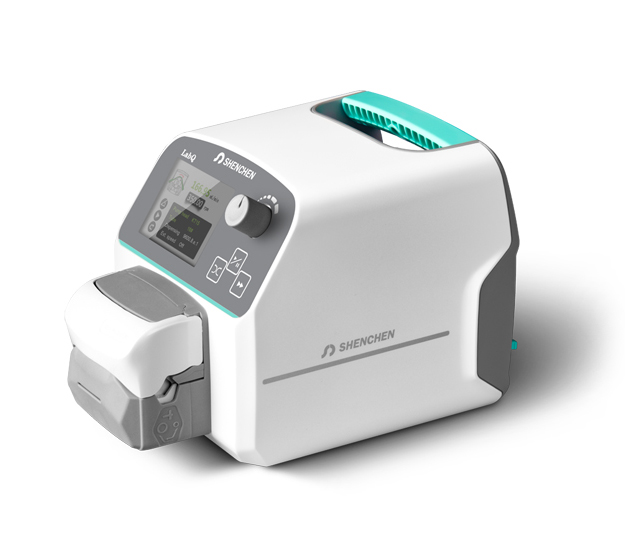

Barrel pumps

Transfer solutions for closed containers

Barrel pumps are designed to efficiently transfer fluids from sealed containers such as drums, barrels, and other containers. They are ideal for a wide range of products, including corrosive, food-grade, chemical, and cosmetic fluids.

Hygiene: Certified compliant with FDA standards

Materials: 316 stainless steel, PP, PVDF, Aluminum

Power supply: Electric and pneumatic options

Main characteristics of barrel pumps

- Long hose design for immersion in closed containers

- Integrated fan for efficient transfer start-up

- Power options: electric or pneumatic depending on the application

- Available materials: 316 stainless steel, polypropylene, PVDF and aluminum

- FDA certifications for food and pharmaceutical applications

- Suitable for drums, barrels, IBCs and other standard containers

- Eliminating waste and improving operational safety

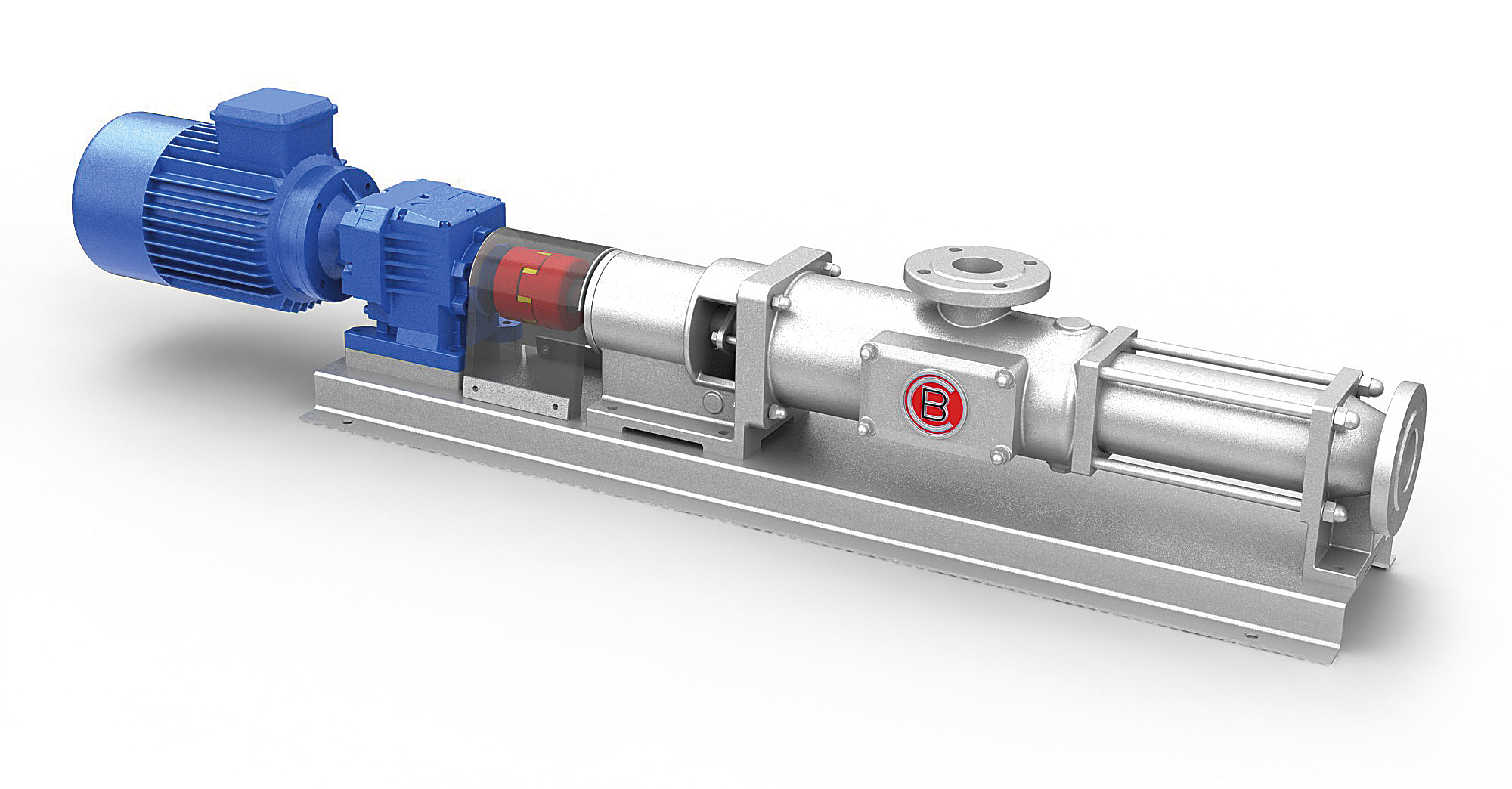

Operating principle

Barrel pumps are a type of long-pipe pump designed to transfer fluids from closed containers. The transfer occurs by immersing the pump's pipe in the closed container holding the fluid. The discharge begins when a fan located at the end of the pipe, inside the barrel, is activated by a motor.

These closed containers can hold acidic, basic, corrosive, aggressive, alkaline, flammable and combustible fluids, as well as liquid soap, honey, chocolate, molasses, cream, jelly, paste, glue, jam, shampoo, paint, and many other products.

Advantages of barrel pumps

Using a drum pump eliminates hazardous practices such as tipping drums to empty them, which poses a health risk to workers and causes product waste and pollution. The drum pump enables a controlled, safe, and efficient transfer of fluids from their containers.

Typical applications:

- Transfer of industrial chemicals

- Handling of food and pharmaceutical fluids

- Emptying of cosmetic product containers

- Transfer of paints and coatings

- Handling of adhesive products and glues

Industrial application areas

Agrifood

Hygiene, safety, and process efficiency are paramount in the food and beverage industry. Our easy-to-clean and hygienic stainless steel solutions ensure safe operation across a wide range of production lines, from dairy and beverages to fruit juice and beer production.

Automobile

In the automotive industry, temperature control and fluid management are essential in processes such as production lines, testing systems, and paint applications. Our compact and robust equipment ensures energy efficiency and operational continuity in these processes.

Marine

Marine applications demand equipment that can withstand extreme environmental conditions and has a long service life. Our saltwater-resistant, low-maintenance solutions reliably provide cooling, heating, and fluid control in ship systems.

HVAC

Efficiency and longevity are essential for air conditioning and domestic hot water systems. Our heating, cooling, ventilation, and domestic hot water solutions optimize energy savings and system performance in the building sector.

Petrochemical and Pharmaceutical

These industries require equipment capable of withstanding high temperatures and pressures. They also require system solutions that can handle corrosive and aggressive gases and liquids. We offer robust structures that meet these requirements, thus ensuring process safety and continuity.

Metallurgical industry

Systems subjected to high temperatures and pressures during metalworking processes require durable and long-lasting solutions. Our products, which guarantee reliability and process stability on industrial production lines, optimize productivity.

Energy

Efficiency is crucial for power generation, cogeneration, and heat recovery systems. Our high-performance solutions help reduce energy costs while ensuring the sustainable operation of these systems.

Textile

Temperature control and energy efficiency are essential in processes such as printing, dyeing, finishing, and drying. Our solutions, specifically designed for textile production processes, improve operational efficiency and optimize energy consumption.

Technical advantages of barrel pumps

• Secure transfer from sealed containers

• Elimination of risks associated with manual tilting

• Significant reduction in product waste

• Compliant with FDA standards for food applications

• Suitable for corrosive and aggressive fluids

• Electric and pneumatic options available

• Various materials depending on the application (316 stainless steel, PP, PVDF, aluminum)

• Easy to install and use

• Minimal maintenance required

• Compatible with standard drums, barrels and IBCs

Frequently Asked Questions

Fluid Transfer Products

Hello! Click below to chat with our team on WhatsApp.