Piston Pumps

High-precision volumetric pumps for sensitive food products

The DOSE-P Series piston pumps offer extremely precise and repeatable dosing for critical food applications. Their positive displacement design ensures dosing accuracy of up to ±0.5% and exceptional consistency, even with products of varying viscosity such as drinkable yogurts, sauces, and compotes.

Flow rate: 50 to 5,000 L/h

Pressure: Up to 40 bar

Accuracy: ±0.5% to ±1%

Main characteristics of piston pumps

- Piston design with FDA/EC1935 certified food-grade seals

- Body made of 316L stainless steel, AISI 304 or special alloys

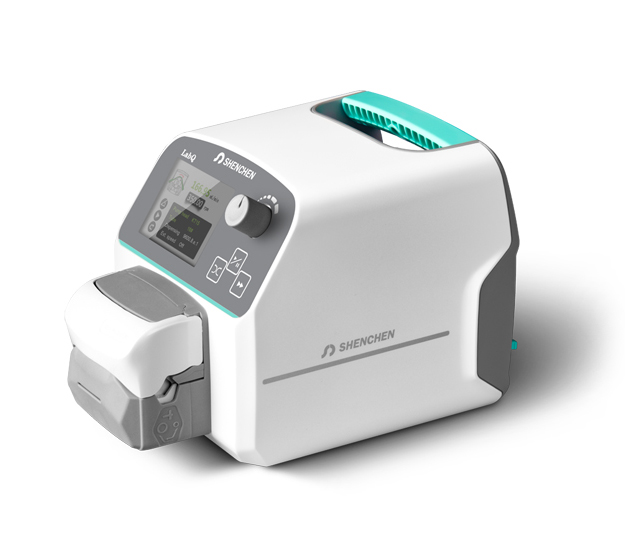

- Electronic control system with touchscreen

- Removable pump head for easy cleaning and maintenance

- PTFE/EPDM/FKM seal depending on application and product

- Compliant with EHEDG and 3A Sanitary Standards

- CE, ATEX certifications for explosive areas (option)

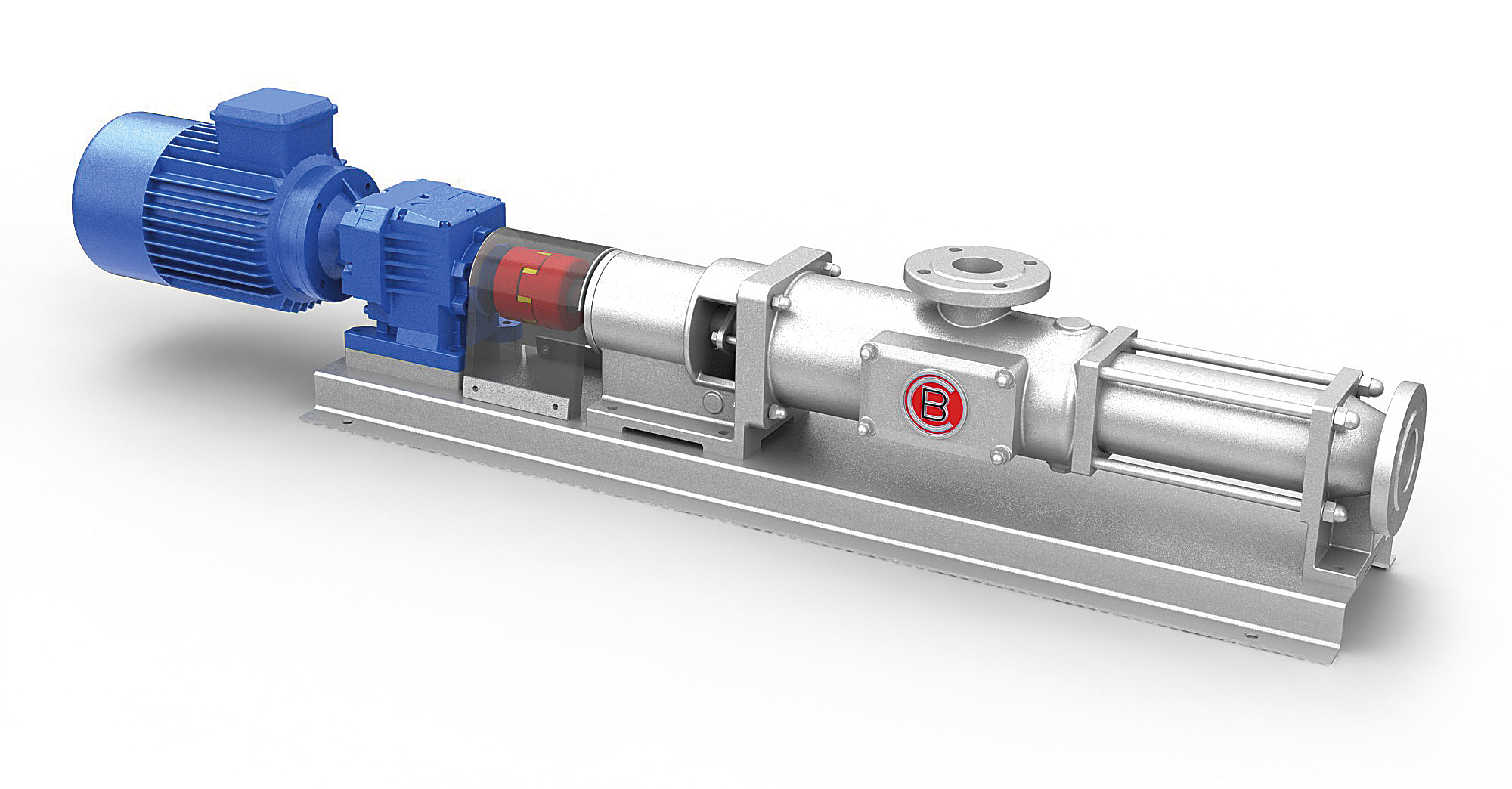

Operating principle

The DOSE-P Series piston pumps utilize a positive displacement mechanism where a piston moves back and forth within a cylinder to transfer precise volumes of product. The piston's precise movement allows for the aspiration and dispensing of accurately measured quantities of fluid, ensuring exceptional dosing repeatability.

This technology is particularly well-suited to sensitive food products because it minimizes shearing and preserves product integrity, even for products containing suspended particles. The electronic control system allows for precise flow and pressure control, with fine adjustments to adapt to different viscosities and product characteristics.

Types of piston pumps available

Flow rate range: 50 L/h to 5,000 L/h

Maximum pressure: Up to 40 bar

Materials: 316L stainless steel - AISI 304 - Special alloys

Seal types: PTFE - EPDM - FKM depending on the application

Dosage accuracy: ±0.5% to ±1%

Maximum viscosity: Up to 50,000 cP

Operating temperature: -10°C to +140°C

Main variants:

- Single-acting piston pumps for standard applications

- Double-acting piston pumps for continuous flow rates

- Multiplex piston pumps (2, 3, 4 pistons) for high flow rates

- Sanitary versions with mirror finish and tri-clamp fittings

- ATEX versions for explosive atmospheres

- Compact pumps for space-constrained production lines

Industrial application areas

Dairy industries

Precise dosing of drinkable yogurts, fermented milks, dessert creams, and fresh cheeses. The piston technology preserves the delicate texture of dairy products while guaranteeing the dosing accuracy essential for adhering to recipes and ensuring consistent quality in finished products.

Sauces and condiments

Dosing mayonnaise, ketchup, tomato sauces, salad dressings, and soy sauces with unparalleled precision. Ability to handle varying viscosities and products containing particles without altering the product structure.

Fruit products

Delicate dosing of compotes, fruit coulis, purees and fruit concentrates. The piston system minimizes shearing and preserves the integrity of the fruit and particles, essential for maintaining the organoleptic quality of the products.

Drinks

Precise dosing of smoothies, nectars, energy drinks, and syrups. The hygienic design and ease of cleaning ensure perfect hygiene that meets the strict standards of the beverage industry.

Culinary preparations

Dosing of soups, cream soups and pastry preparations. The versatility of the pumps allows adaptation to different viscosities and textures while maintaining exceptional dosing accuracy.

Pharmaceutical industry

Critical dosing of active ingredients, excipients, and intermediate products. Precision and reproducibility are essential to comply with strict formulations and pharmaceutical standards.

Cosmetic

Dispensing of creams, lotions, gels and skincare products. Piston technology preserves the properties of emulsions and shear-sensitive formulas.

Biotechnology

Assay of culture media, enzymes and biological products. Aseptic design and compatible materials ensure the integrity of sensitive biological products.

Technical advantages of piston pumps

• Exceptional dosage accuracy (±0.5% to ±1%)

• Excellent repeatability even after many cycles

• Ability to handle viscosities up to 50,000 cP

• Sanitary design with smooth surfaces and rounded corners

• Clean-in-place (CIP) possible

• Reduced maintenance and long service intervals

• Compatible with food, pharmaceutical and cosmetic products

• Precise electronic control with touchscreen

• Operating temperature from -10°C to +140°C

• Operating pressure up to 40 bar

Advantages of piston dosing

Unparalleled precision

Volumetric piston dosing guarantees an accuracy of ±0.5% to ±1%, essential for adherence to recipes, reduction of material costs and consistent quality of finished products.

Product versatility

Ability to dose products of highly variable viscosities (up to 50,000 cP) and containing suspended particles, without altering the product structure.

Hygiene and cleanability

Sanitary design with smooth contact surfaces, rounded corners and clean-in-place (CIP) capability to meet the strictest hygiene standards of the food industry.

Frequently Asked Questions

Fluid Transfer Products

Bonjour ! Cliquez ci-dessous pour discuter avec notre équipe sur WhatsApp.