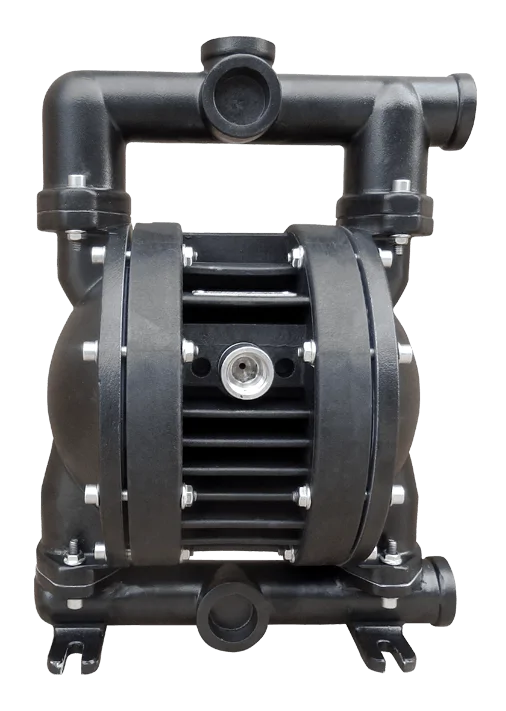

Pneumatic diaphragm pumps

Pneumatic pumps for complex fluids and harsh environments

Pneumatic diaphragm pumps, used for various purposes in many industrial sectors, operate on the principle of suction and pressure. They are not driven by an electric motor; they are powered solely by compressed air.

Safety: Explosion-proof and electricity-free

Suction: Strong suction and dry running

Regulation: Flow and pressure easily adjustable

Main characteristics of pneumatic diaphragm pumps

- Alternatives in PP, PVDF, aluminum and AISI 316 stainless steel

- Can be used in environments with a risk of explosion.

- Eco-friendly design and economical air consumption

- High-efficiency pressure/capacity and oil-free operation

- Near-zero noise level and minimal excessive wear

- Possibility of using additional frost protection

- New air valve design with fully controlled airflow

Operating principle

Diaphragm pumps operate on a principle similar to that of suction and discharge pumps. Pneumatic diaphragm pumps are driven by compressed air, not an electric motor. They are connected to the air line of a compressor of appropriate capacity, depending on the pump's flow rate and the pressure required by the operating conditions.

Ruby diaphragm pumps offer superior pumping performance thanks to an innovative design. This improved design also allows the use of alternative materials for hydraulic components without compromising pressure efficiency.

Advanced features of composite diaphragms

The advanced composite membrane ensures a higher flow rate per cycle, resulting in increased performance. Furthermore, its ease of installation and maintenance, along with its extended lifespan, helps reduce operating costs.

Advantages of composite diaphragms:

- Easy installation and maintenance

- Excellent lifespan

- Reduction of inventory costs

- Improved performance

- Larger movement per turn

- The risk of leakage is eliminated because there is no central opening.

- The main axis does not need to be insured

- Screws and unscrews without tools

Industrial application areas

Agrifood

Hygiene, safety, and process efficiency are paramount in the food and beverage industry. Our easy-to-clean and hygienic stainless steel solutions ensure safe operation across a wide range of production lines, from dairy and beverages to fruit juice and beer production.

Petrochemical and Pharmaceutical

These industries require equipment capable of withstanding high temperatures and pressures. They also require system solutions that can handle corrosive and aggressive gases and liquids. We offer robust structures that meet these requirements, thus ensuring process safety and continuity.

Automobile

In the automotive industry, temperature control and fluid management are essential in processes such as production lines, testing systems, and paint applications. Our compact and robust equipment ensures energy efficiency and operational continuity in these processes.

Marine

Marine applications demand equipment that can withstand extreme environmental conditions and has a long service life. Our saltwater-resistant, low-maintenance solutions reliably provide cooling, heating, and fluid control in ship systems.

Textile

Temperature control and energy efficiency are essential in processes such as printing, dyeing, finishing, and drying. Our solutions, specifically designed for textile production processes, improve operational efficiency and optimize energy consumption.

Energy

Efficiency is crucial for power generation, cogeneration, and heat recovery systems. Our high-performance solutions help reduce energy costs while ensuring the sustainable operation of these systems.

Technical advantages of pneumatic diaphragm pumps

• Explosion-proof operation without electricity

• Strong suction and dry running possible

• Easily adjustable flow and pressure

• Safe transfer of flammable and combustible fluids

• Eco-friendly design and economical air consumption

• High-efficiency pressure/capacity

• Oil-free operation and reduced noise level

• Easy disassembly and reassembly

• Automatic suction and easily adjustable intake direction

• Enclosed design for harsh environments

Frequently Asked Questions

Fluid Transfer Products

Hello! Click below to chat with our team on WhatsApp.